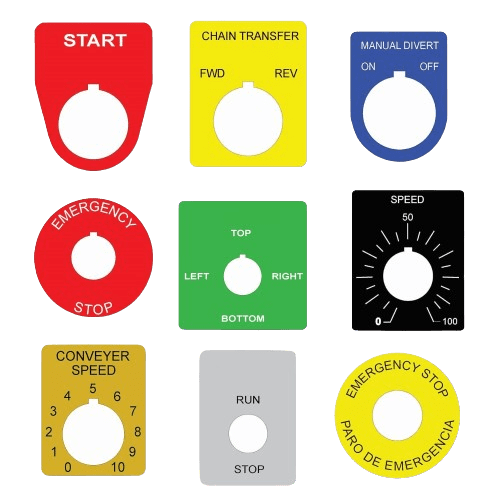

Custom Front Panels-Custom Faceplates

A front panel, in the context of electronic devices and equipment, refers to the face or front surface of a device that is accessible to the user. It’s the part of a device that the user interacts with and typically contains various controls, indicators, displays, and input/output ports. The design of the front panel is crucial for user interface and functionality.

Examples of devices with front panels include audio equipment, computer cases, home appliances, electronic instruments, and many other electronic devices. The design of the front panel is not only functional but also contributes to the overall aesthetic appeal of the device.

Considering factors like durability, weight, and cost, front panels usually are made of aluminum and stainless steel.

Here are some common elements found on front panels of electronic devices:

Display/Screen: Many devices have a display or screen on the front panel to provide feedback, information, or a user interface.

Buttons and Controls: Physical buttons, knobs, sliders, or touch-sensitive controls may be present for user input and control of the device.

Indicators: LED lights, numerical displays, or other indicators are often used to convey information about the device’s status or operation.

Ports: Input/output ports such as USB ports, audio jacks, HDMI ports, etc., are often located on the front panel for easy access.

Brand and Model Information: Manufacturers often place their branding and model information on the front panel for identification.

Ventilation: Some devices may have ventilation grilles or fans on the front panel to help dissipate heat generated during operation.

Metal Front Panel Material Compare

Front panels made of aluminum are popular in various industries due to the material’s favorable characteristics. Aluminum offers a combination of properties that make it well-suited for front panel applications:

Lightweight: Aluminum is a lightweight metal, making it easy to handle and install. This is particularly beneficial for portable devices or equipment where weight is a consideration.

Durable: Aluminum is corrosion-resistant, which enhances the durability of front panels. It can withstand exposure to the elements and resist rusting over time.

Machinability: Aluminum is relatively easy to machine, allowing for precise cutting, drilling, and shaping. This makes it an ideal material for creating intricate designs and features on front panels.

Thermal Conductivity: Aluminum has good thermal conductivity, which helps dissipate heat efficiently. This is essential for electronic devices that generate heat during operation.

Aesthetic Appeal: Aluminum has a sleek and modern appearance, contributing to the aesthetic appeal of front panels. It is often chosen for its ability to provide a professional and high-quality look.

Anodizing Possibility: Aluminum can be anodized, a process that adds a protective oxide layer to the surface, improving corrosion resistance and allowing for various color options.

Recyclability: Aluminum is highly recyclable, making it an environmentally friendly choice. Recycling aluminum requires significantly less energy compared to producing new aluminum.

Cost-Effective: Aluminum is cost-effective compared to some other metals, offering a balance between performance and affordability.

When creating front panels from aluminum, manufacturers often use processes such as CNC machining, laser cutting, or stamping to achieve the desired shapes and features. The surface finish can be left raw for a natural aluminum look or treated with various coatings or finishes, such as anodizing or powder coating, to enhance durability and aesthetics.

Front panels made of stainless steel are another popular choice, especially in applications where durability, corrosion resistance, and a sleek appearance are crucial. Stainless steel is an alloy composed of iron, chromium, nickel, and other elements, and it is known for its robust properties. Here are some key advantages and considerations for front panels made of stainless steel:

Corrosion Resistance: Stainless steel is highly resistant to corrosion, making it suitable for applications where the front panel may be exposed to harsh environmental conditions or frequent contact with liquids.

Durability: Stainless steel is a durable and robust material, providing longevity to front panels. It can withstand physical impact and resist scratches and dents, maintaining a polished appearance over time.

Hygienic Properties: Stainless steel has hygienic properties, making it suitable for applications in healthcare, food processing, and other industries where cleanliness is essential.

Temperature Resistance: Stainless steel can withstand a wide range of temperatures, making it suitable for applications where the front panel may be exposed to heat or extreme cold.

Aesthetic Appeal: Stainless steel has a sleek and modern appearance, often associated with high-end and premium products. It can contribute to a professional and sophisticated look for front panels.

Ease of Cleaning: Stainless steel surfaces are easy to clean and maintain. This is particularly important in environments where hygiene is a priority.

Variety of Finishes: Stainless steel can be finished in various ways, including polished, brushed, or textured finishes. These finishes provide different aesthetic options to suit the design requirements.

Machinability: While not as easy to machine as aluminum, stainless steel can be machined and shaped with precision using methods like CNC machining.

Cost: Stainless steel is generally more expensive than aluminum, so the choice of material may depend on the specific requirements and budget constraints.

Front panels made of stainless steel are commonly used in industrial equipment, medical devices, control panels, and high-end consumer electronics where a combination of durability, corrosion resistance, and a polished appearance is desired. The manufacturing process for stainless steel front panels may involve cutting, machining, and finishing to achieve the desired design and functionality.

Custom Metal Front Panel FAQs

1. What’s the MOQ?

Usually, MOQ is 100-500pcs

2. What’s the price?

The price depends on material, size, color, and quantity. So when you send an inquiry to us pls send as more detailed information as possible.

3. What file we should provide when producing the metal front panel?

Ai, PDF, CAD, STP or IGES file

4. What’s the metal front panel thickness?

0.2-3mm depending on you

5. What’s the production time?

Usually around 7-15 days