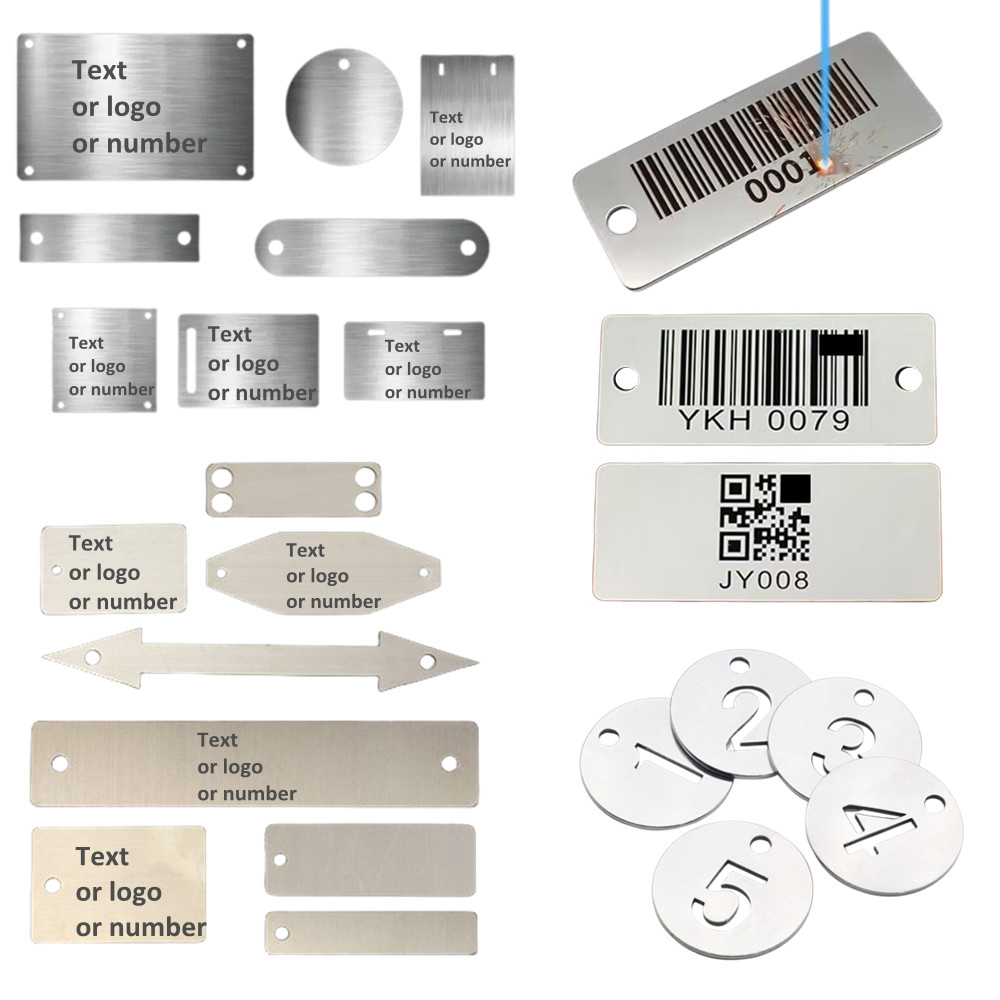

Custom Blank Metal Tags For Engraving

Custom blank stainless steel tags are versatile and durable, making them an excellent choice for a variety of applications, including industrial, commercial, and personal uses. These tags provide a blank canvas for engraving, allowing for detailed and permanent customization.

Applications

- Industrial and Commercial Use:

- Equipment and machinery identification

- Asset tagging and inventory control

- Valve and pipe identification

- Compliance and safety labeling

- Consumer Products:

- Custom tags for electronics and appliances

- Personalized tags for fashion accessories and jewelry

- Labels for home decor and furniture

- Outdoor and Marine Use:

- Tags for marine equipment

- Garden and outdoor furniture tags

- Weather-resistant applications

- Personal and Promotional Use:

- Custom engraved keychains

- Pet ID tags

- Personalized nameplates

- Corporate gifts and promotional items

Finish: Stainless steel tags can have different finishes, such as brushed, polished, or matte. A brushed finish is popular for a more refined look, while a polished finish provides a mirror-like appearance.

For customized blank stainless steel tags, there is no limit to shape, color, and size.

How To Engrave Stainless Steel Tag?

There are several methods for engraving stainless steel tags. Most common use engraving methods including

Laser Engraving: This is a precise method that uses a laser beam to etch the surface of the stainless steel. It can produce intricate designs, text, and even barcodes with high accuracy.

Chemical Etching: Chemical etching involves using a chemical process to selectively remove layers of stainless steel, creating a permanent engraving. It’s often used for intricate designs and fine details.

Custom Blank Aluminum Tags For Engraving

Aluminum tags for engraving are durable and versatile identification solutions used in various industries and applications. They are commonly used for labeling, tracking, and identifying objects, equipment, and products. Aluminum tags are chosen for their lightweight nature, resistance to corrosion, and ease of customization through engraving.

The cost of aluminum tags for engraving can vary based on factors like tag size, engraving complexity, quantity ordered, and any additional customization. Generally, aluminum tags are considered cost-effective for the level of durability and customization they offer.

For customized blank aluminum tags, there is no limit to shape, color, and size.

How To Engrave Aluminum Tag?

Aluminum tags can be engraved using various techniques, including laser engraving and stamping.

Laser Engraving: This is a precise method that uses a laser beam to etch the surface of the aluminum tag. It can produce intricate designs, text, and even barcodes with high accuracy.

Stamping involves using a die to press or impress characters, numbers, logos, or designs onto the surface of the aluminum tag. This process creates a raised or indented impression on the tag, which can be easily read and felt.

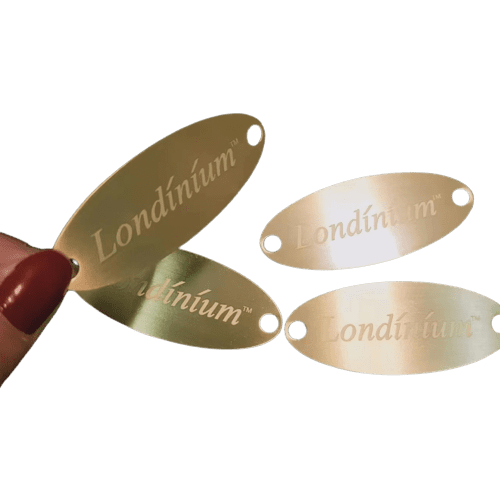

Custom Blank Brass Tags For Engraving

Brass tags are another popular choice for engraving due to their aesthetic appeal, durability, and versatility.

Brass has a classic and elegant appearance, often associated with quality and professionalism.

Engraving on brass tags creates a distinctive, high-quality mark that can be used for various identification and labeling purposes including Industrial equipment identification, Asset management, valve tags, Key tags, Nameplates, Personalized gifts and awards, etc.

For customized blank brass tags, there is no limit to shape, and no limit to size.

How To Engrave Brass Tag?

Engraving a brass tag can be done using a few different methods, each with its own level of complexity and equipment requirements.

Laser Engraving: This is a precise method that uses a laser beam to etch the surface of the brass tag. It can produce intricate designs and text.

Stamping brass tags involves using pressure to create raised or indented marks on the surface of the tag. This method is often used to create permanent and tactile identification marks on brass tags. Machine stamping provides more controlled and uniform marks, especially for larger quantities.

Custom Blank Metal Tags For Engraving FAQs

1. What’s the MOQ for custom blank metal tags?

No minimum order quantity is required for our existing blank metal tags. For customized blank metal tags usually MOQ is 500-1000pcs.

2. What materials are available for custom blank metal tags?

Common Materials: Aluminum, stainless steel, brass, copper, and anodized aluminum are frequently used.

3. Which parts we can customize?

Metal tag material, shape, size, thickness, color, and surface finish can be customized.

4. What’s the price?

Price is decided by many factors. So when you send an inquiry to us please send details as much as possible. We can ensure you that our price is very competitive on the market.

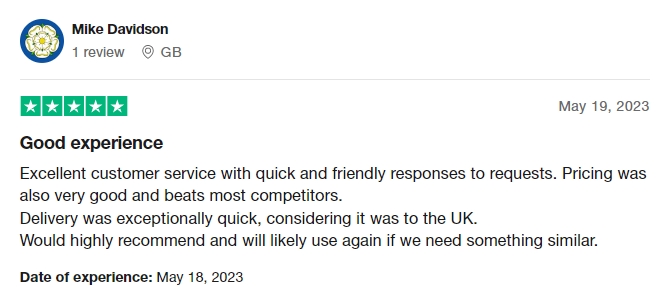

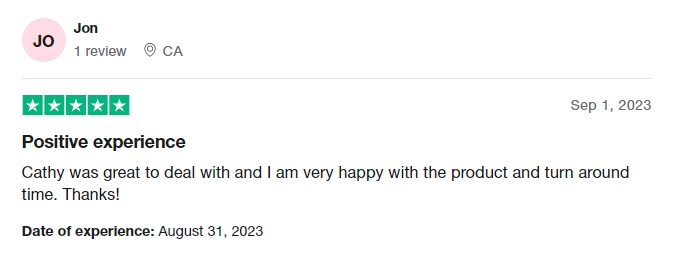

What our customers say?